Proper engine maintenance is crucial for any sailor, and building a custom engine room ventilation system is a great way to ensure optimal engine performance and longevity.

Building a Custom Engine Room Ventilation System

Welcome to another informative article in our Boat Modifications and Upgrades section. Today, we will be discussing a crucial aspect of engine maintenance and upgrades: building a custom engine room ventilation system. As you embark on your sailing adventures with your family, ensuring the proper functioning and longevity of your boat’s engine is of utmost importance. One way to achieve this is by having an efficient engine room ventilation system in place.

In this comprehensive guide, we will cover the following topics:

- The importance of engine room ventilation

- Types of engine room ventilation systems

- Components of a custom engine room ventilation system

- Designing and building your custom engine room ventilation system

- Maintenance tips for your ventilation system

The Importance of Engine Room Ventilation

Before diving into the details of building a custom engine room ventilation system, let’s first understand why it is so important. Proper engine room ventilation serves several purposes:

-

Temperature regulation: Engines generate a significant amount of heat during operation. A well-designed ventilation system helps dissipate this heat, preventing overheating and ensuring optimal engine performance.

-

Moisture control: Boats are constantly exposed to moisture, which can lead to corrosion and other issues in the engine room. A good ventilation system helps maintain a dry environment, reducing the risk of moisture-related problems.

-

Air quality: Engines consume oxygen and produce exhaust gases, including carbon monoxide, which can be harmful if not properly vented. A well-ventilated engine room ensures a continuous supply of fresh air, reducing the risk of dangerous gas buildup.

-

Noise reduction: A well-insulated and ventilated engine room can help reduce engine noise, making your sailing experience more enjoyable.

Types of Engine Room Ventilation Systems

There are two main types of engine room ventilation systems: passive and active.

Passive Ventilation Systems

Passive ventilation systems rely on natural airflow to circulate air in and out of the engine room. This can be achieved through strategically placed vents, louvers, or ducts that allow air to flow freely. Passive systems are generally low-cost and low-maintenance, but they may not provide adequate airflow in all situations, especially in larger engine rooms or in extreme temperature conditions.

Active Ventilation Systems

Active ventilation systems use fans or blowers to force air in and out of the engine room. These systems provide more control over airflow and can be more effective in maintaining optimal temperature and air quality. However, they also require more maintenance and consume additional power.

For most boats, a combination of passive and active ventilation is recommended to achieve the best results.

Components of a Custom Engine Room Ventilation System

When designing your custom engine room ventilation system, you will need to consider the following components:

-

Intake and exhaust vents: These are the openings through which fresh air enters and stale air exits the engine room. They should be strategically placed to ensure proper airflow and prevent the recirculation of exhaust gases.

-

Ducts: Ducts are used to channel air between the intake and exhaust vents and the engine room. They should be properly sized and insulated to minimize heat transfer and noise.

-

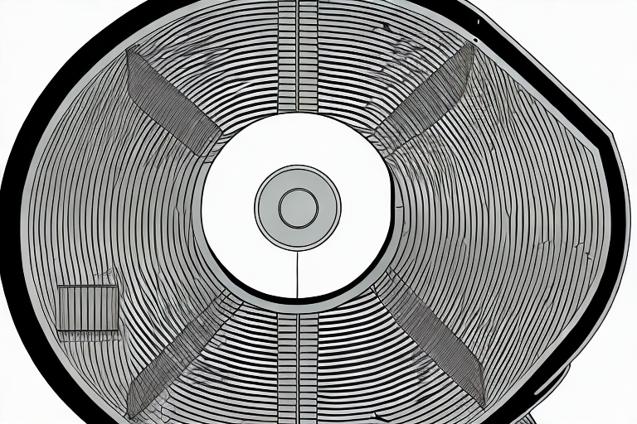

Fans or blowers: If you choose to incorporate active ventilation, you will need fans or blowers to force air through the system. These should be sized according to the airflow requirements of your engine room.

-

Air filters: Air filters help remove dust, debris, and other contaminants from the incoming air, protecting your engine and other components. They should be easily accessible for cleaning and replacement.

-

Moisture control: Depending on your boat’s environment, you may need to incorporate moisture control measures, such as dehumidifiers or moisture-absorbing materials, to maintain a dry engine room.

-

Temperature and humidity sensors: These sensors can help you monitor the conditions in your engine room and adjust your ventilation system as needed.

Designing and Building Your Custom Engine Room Ventilation System

Now that you have a basic understanding of the components involved, let’s discuss the process of designing and building your custom engine room ventilation system.

-

Assess your needs: Begin by evaluating your current engine room conditions and identifying any issues, such as excessive heat, moisture, or poor air quality. Determine the airflow requirements for your engine room based on the size and type of engine, as well as any additional heat-generating equipment.

-

Choose your ventilation type: Decide whether you will use a passive, active, or combination ventilation system. Consider factors such as your boat’s size, engine room layout, and your desired level of control over airflow.

-

Plan your intake and exhaust vents: Determine the optimal locations for your intake and exhaust vents, ensuring that they are positioned to promote proper airflow and prevent the recirculation of exhaust gases. Keep in mind that intake vents should be located low on the hull, while exhaust vents should be higher up to take advantage of the natural rise of hot air.

-

Design your ductwork: Plan the layout of your ducts, taking into account the size and shape of your engine room, as well as any obstacles or equipment that may impede airflow. Ensure that your ducts are properly sized and insulated to minimize heat transfer and noise.

-

Select your fans or blowers: If using active ventilation, choose fans or blowers that are appropriately sized for your airflow requirements. Consider factors such as power consumption, noise levels, and ease of maintenance.

-

Incorporate air filters and moisture control: Choose air filters that are suitable for your environment and ensure that they are easily accessible for cleaning and replacement. If necessary, incorporate moisture control measures, such as dehumidifiers or moisture-absorbing materials.

-

Install temperature and humidity sensors: Install sensors to help you monitor the conditions in your engine room and adjust your ventilation system as needed.

-

Build and install your system: Once you have designed your custom engine room ventilation system, gather the necessary materials and tools, and begin the installation process. Be sure to follow all safety precautions and consult with a professional if you are unsure about any aspect of the installation.

Maintenance Tips for Your Ventilation System

To ensure the longevity and proper functioning of your custom engine room ventilation system, regular maintenance is essential. Here are some tips to help you keep your system in top shape:

-

Clean and replace air filters: Regularly inspect your air filters for signs of dirt and debris, and clean or replace them as needed.

-

Inspect and clean ducts: Periodically inspect your ducts for any obstructions or buildup of dust and debris. Clean them as necessary to maintain proper airflow.

-

Check fans or blowers: If using active ventilation, regularly inspect your fans or blowers for signs of wear or damage. Clean and lubricate them as needed, and replace any worn or damaged parts.

-

Monitor temperature and humidity: Keep an eye on your engine room’s temperature and humidity levels, and adjust your ventilation system as needed to maintain optimal conditions.

-

Inspect and maintain moisture control measures: If using dehumidifiers or moisture-absorbing materials, regularly inspect and maintain them to ensure their effectiveness.

By following these maintenance tips and investing in a well-designed custom engine room ventilation system, you can help ensure the longevity and proper functioning of your boat’s engine, making your sailing adventures with your family more enjoyable and worry-free.

We hope this comprehensive guide has provided you with valuable information and insights on building a custom engine room ventilation system. As you continue to embrace the freedom and fulfillment of your unconventional sailing lifestyle, remember that proper engine maintenance and upgrades are essential to your boat’s performance and your family’s safety. Happy sailing!